BST

|

INTERCHANGE STANDARD |

Parker ST – DNP ST – Dixon E |

|

APPLICATION |

It is ideal for high pressure water and steam washing equipment, carpet cleaners, food industry, dye transfer lines & mold coolant lines. |

|

CHARACTERISTICS |

A broad range of metals (brass, steel and stainless steel) and seals materials allows their use with most fluids. |

SPECIFICATION

|

|

MATERIALS: |

Body Components in brass |

|

SEALS: |

Standard in FKM. On request NBR, EPDM seals. |

|

|

BACK-UP RING: |

PTFE |

|

|

WORKING TEMPERATURE: |

With standard seals -25°C to +200°C |

|

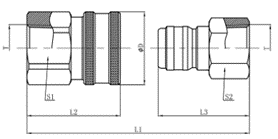

CH&J(F) |

CH&J (M) |

ISO |

L1 |

L2 |

L3 |

Ø D |

S1 |

S2 |

T |

|

BST-2 |

BST-N2 |

6.3 |

52.5 |

37.3 |

34 |

24 |

20.5 |

17.5 |

1/4" NPT |

|

BST-3 |

BST-N3 |

10 |

56.2 |

38 |

40 |

28 |

22.2 |

20.6 |

3/8” NPT |

|

BST-4 |

BST-N4 |

12.5 |

63 |

41.3 |

44.6 |

33.5 |

28.5 |

25.4 |

1/2" NPT |

TECHNICAL DATA

| NOMINAL SIZE | MAX. WORKING PRESSURE | RATED FLOW | |

| CH&J | ISO | (BAR) | (L/M) |

| BST-2 | 6.3 | 350 | 6 |

| BST-3 | 10 | 180 | 12 |

| BST-4 | 12.5 | 150 | 12 |